High-performance PE and PP packaging films for safe food and consumer goods applications, offering excellent sealability, outstanding print quality, and strong product protection across manual and high-speed packing lines. All POLIFILM All-in-One, MDO PE, and Retort films are 100% recyclable, supporting the EU’s 2030 recyclable packaging goals and a sustainable circular economy.

POLIFILM was founded in 1972 in Germany, starting with the production of high-performance PE and PP films. Today, it stands as a global leader in flexible packaging solutions with production and distribution facilities across Europe, Asia (including Vietnam), and the Americas. With a strong focus on sustainability and innovation, POLIFILM supports brands worldwide in creating recyclable, future-ready packaging.

Products

ALL-IN-ONE PE & PP FILM

Mono-material films (either PE or PP) that combine print, barrier, and sealing layers into one structure. Eliminating the need for complex laminates.

BEST USED FOR:

- Snack pouches, dry food packaging, household products

- Digital or flexographic printing applications

- Fully recyclable packaging structures

KEY BENEFITS:

- One film, multiple functions

- Suitable for high-speed converting and filling

- Reduced production steps and cost-saving

THE CHALLENGE OF TRANSITIONING TO MONO-MATERIAL PACKAGING

MDO-PE FILM

PE film enhanced through mono-directional orientation, improving clarity, stiffness, and barrier performance. A sustainable alternative to PET and OPP films.

BEST USED FOR:

- Stand-up pouches, food sachets, Frozen food

- Labels, overwraps, and flexible packaging for premium goods

- Form-fill-seal packaging systems

KEY BENEFITS:

- Excellent oxygen barrier (with EVOH)

- High print quality (gravure, flexo, digital)

- 100% recyclable mono-material solution

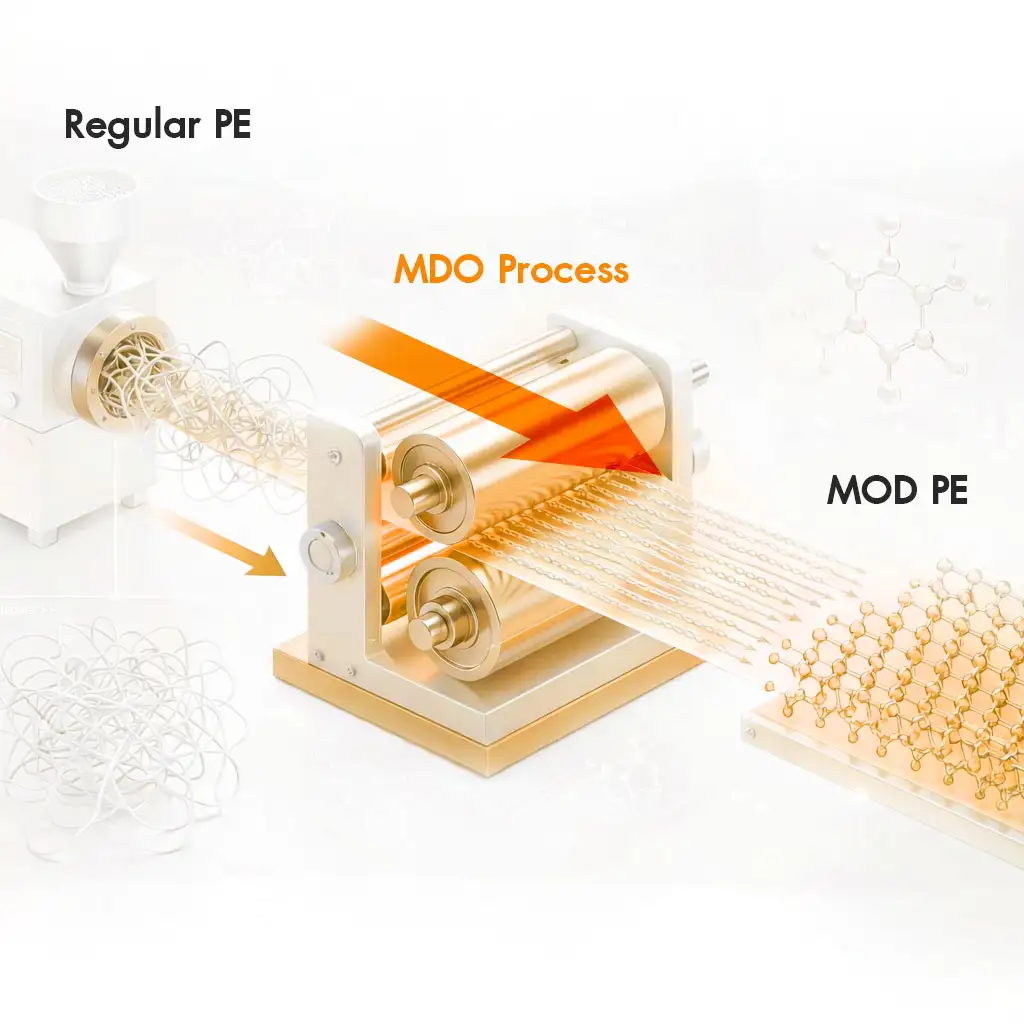

THE SCIENCE OF STRENGTH HOW MDO TECHNOLOGY UNLOCKS PERFORMANCE

MDO (Machine Direction Orientation) is a process that stretches the film in a single direction (mono-axially).

This reorients the polymer molecules from a tangled state into a highly aligned structure, fundamentally changing the film’s properties.

- Increases stiffness and strength (High Stiffness).

- Enhances optical properties (Transparency and Gloss).

- Improves printability.

- Boosts inherent barrier properties against oxygen.

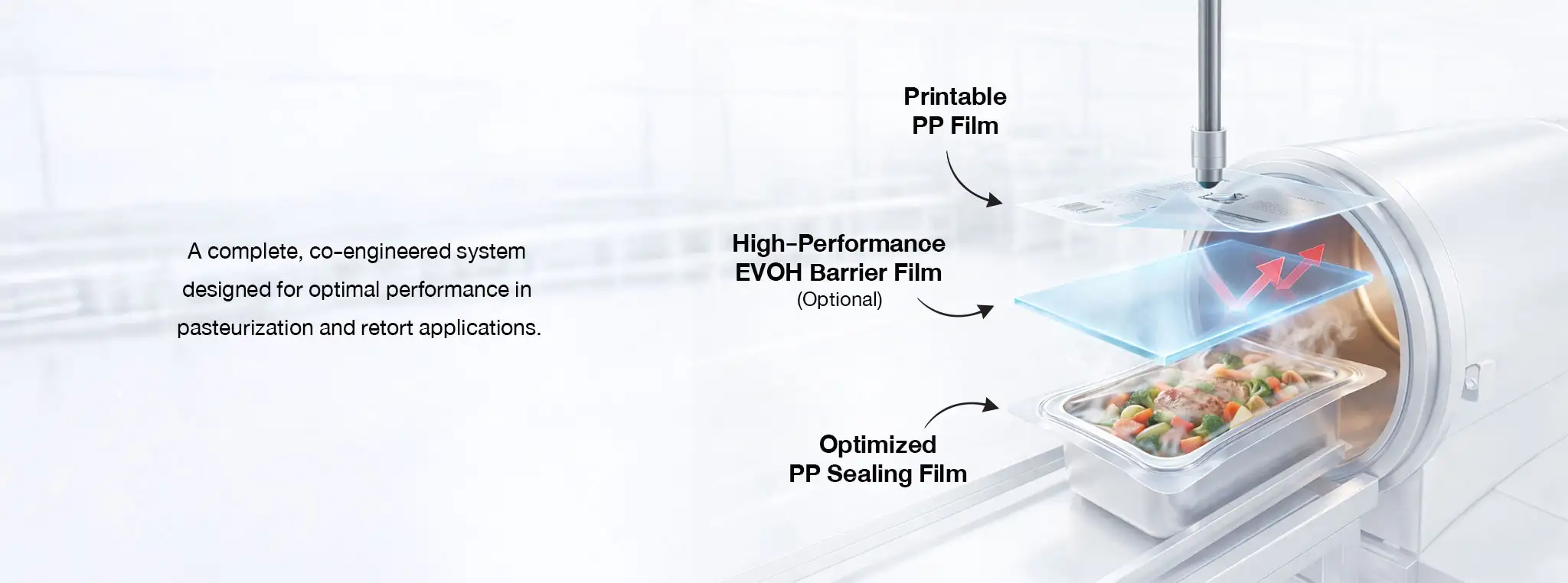

RETORT PP FILM

A specially engineered PP film system for packaging that requires sterilization or high-heat treatment, such as retort processing.

BEST USED FOR:

- Ready meals, soup pouches, microwaveable packaging

- Long shelf-life food products

- Applications requiring high thermal resistance

- Processed foods that require pasteurization or retort processing

KEY BENEFITS:

- Thermal stability during retort

- Complete mono-material PP structure (base + barrier + seal)

- Designed for recycling without sacrificing protection

THE POLIFILM RETORT SYSTEM: THREE CORE COMPONENTS